Increase Efficiency: Exactly How Updating Undercarriage Parts Can Improve Effectiveness

Increase Efficiency: Exactly How Updating Undercarriage Parts Can Improve Effectiveness

Blog Article

Maximize Efficiency With Resilient Undercarriage Components

In the realm of hefty equipment and tools, the duty of undercarriage components is vital in making sure optimal performance and longevity. The effectiveness and efficiency of these elements can dramatically affect the total procedure of equipment, making the option of sturdy undercarriage components an essential decision for operators and managers alike.

Benefits of Using Durable Undercarriage Parts

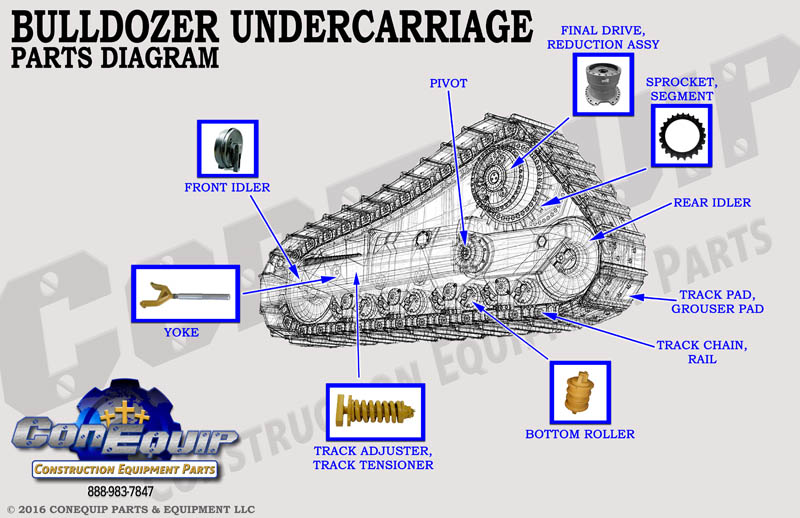

Utilizing durable undercarriage components not just boosts the long life of hefty machinery however also reduces maintenance costs considerably. By purchasing premium undercarriage components, such as tracks, sprockets, idlers, and rollers, equipment drivers can experience boosted uptime and enhanced overall performance.

Moreover, the durability of hefty machinery is directly linked to the high quality of its undercarriage components. Sturdy components can endure the rigors of requiring applications, making certain that the equipment remains operational for prolonged periods. Therefore, drivers can stay clear of pricey downtime and upkeep expenses, ultimately optimizing the roi for their equipment.

Factors Impacting Undercarriage Resilience

The resilience of undercarriage components in hefty machinery is affected by different crucial factors that straight influence performance and longevity. High-quality products, such as hardened steel, are essential for holding up against the extreme conditions and hefty loads that undercarriage components are subjected to - undercarriage parts.

Furthermore, ecological aspects can have a significant influence on the durability of undercarriage components. Exposure to unpleasant products, extreme temperature levels, and extreme working conditions can speed up wear and tear on undercarriage parts. Picking undercarriage parts that are particularly made to endure these ecological challenges is important for making certain resilience.

Additionally, the design and engineering of undercarriage parts have a direct impact on their longevity. Components that are designed to distribute loads evenly, decrease friction, and reduce anxiety focus are most likely to have a much longer life-span - undercarriage parts. By taking into consideration these critical factors, equipment operators can make best use of the durability and efficiency of their undercarriage parts

Upkeep Tips for Lengthening Undercarriage Life

Applying normal upkeep routines is vital for prolonging the lifespan of undercarriage components in hefty equipment. To extend the undercarriage life, it is critical to frequently examine for wear and tear. Frequently inspect for absent or loose bolts, harmed rollers, or misaligned tracks, as these problems can escalate and cause more damages if not addressed without delay. In addition, make sure that the undercarriage is click resources correctly lubricated according to supplier standards to reduce rubbing and stop premature wear.

Another essential maintenance pointer is to keep the undercarriage tidy from dirt, rocks, and particles. Buildup in the undercarriage can increase wear and corrosion, causing costly repair services. Washing the undercarriage after procedure in harsh problems is advised to avoid these concerns.

Finally, monitoring and recording upkeep activities can aid in creating a positive upkeep schedule. Keeping thorough records of fixings, replacements, and evaluations can supply beneficial understandings into the undercarriage's condition and performance gradually, assisting in forecasting and preventing potential failures. By complying with these upkeep ideas diligently, drivers can dramatically increase the resilience and performance of undercarriage parts in heavy machinery.

Choosing the Right Undercarriage Parts

Choosing suitable undercarriage elements is vital for making the most of the effectiveness and longevity of heavy machinery. There are numerous aspects to think about when it comes to selecting the best undercarriage components. One key factor is recognizing the details needs of the machine and the environment in which it will run. Different applications might require different kinds of undercarriage parts, such click site as tracks, rollers, idlers, and gears. It is important to pick elements that are developed to withstand the certain conditions the machine will certainly come across, whether it be rough surface, rough products, or severe temperatures.

In addition, thinking about the quality and track record of the manufacturer is crucial. Choosing reputable brands recognized for producing high-performance and resilient undercarriage components can significantly affect the total effectiveness and durability of the equipment. Ensuring that the elements are suitable with the machine design and effectively installed is essential for ideal efficiency. By carefully selecting the best undercarriage elements, tools owners can enhance efficiency, minimize downtime, and expand the life-span of their hefty equipment.

Study: Boosted Performance With Durable Components

Incorporating long lasting undercarriage components has demonstrated substantial enhancements in machinery efficiency. One instance study included a building and construction company that upgraded its excavator's undercarriage parts to more long lasting alternatives.

In another instance, a mining operation changed the undercarriage components of its bulldozer with premium, long lasting choices. This switch resulted in an exceptional renovation in the excavator's maneuverability and overall performance. The device might browse tough surfaces extra efficiently, resulting in improved operational efficiency and lowered gas intake.

Additionally, a logging company bought durable undercarriage parts for its forestry equipment. The upgraded components exhibited prolonged lifespan and increased resistance to abrasion from rough terrain. The business experienced decreased maintenance costs and better tools uptime, eventually improving its bottom check my reference line. These study emphasize the substantial advantages of utilizing durable undercarriage components in maximizing equipment performance and longevity.

Final Thought

Finally, making use of long lasting undercarriage parts can significantly enhance performance and long life of heavy equipment. Aspects such as proper upkeep and choosing the appropriate elements play an essential duty in making best use of undercarriage toughness. By executing these approaches, businesses can reduce downtime, boost efficiency, and eventually reduce operational prices. Study have shown that buying resilient undercarriage components can lead to enhanced total performance and efficiency in numerous markets.

The efficiency and performance of these components can considerably affect the total operation of machinery, making the choice of long lasting undercarriage components a crucial decision for supervisors and drivers alike.Including sturdy undercarriage components has actually demonstrated significant enhancements in machinery performance. These case studies highlight the concrete benefits of utilizing long lasting undercarriage components in enhancing machinery performance and durability.

In final thought, using resilient undercarriage parts can considerably enhance performance and longevity of heavy equipment (undercarriage parts). Instance researches have actually revealed that investing in resilient undercarriage parts can lead to improved total efficiency and efficiency in different industries

Report this page